Design Process

steel can be found in a variety of products and structures – from personal vehicles to the Burj Khalifa: the world’s largest skyscraper. But what is steel, and why is it so important? Steel is an alloy, meaning that it is made by combining iron with another element, usually (but not always) carbon.

1. Initial Chat & Development

Steel Making Process:

There are 3 steps to making steel:

- Iron making

- steel making

- Continuous casting process.

So We Have First Decided & conversation with team members thrown chat and making strategy of development.

2. Design Brief

Steel design, or more specifically, structural steel design, is an area of structural engineering used to design steel structures. ... There are currently two common methods of steel design: The first method is the Allowable Strength Design (ASD) method. The second is the Load and Resistance Factor Design (LRFD) method.

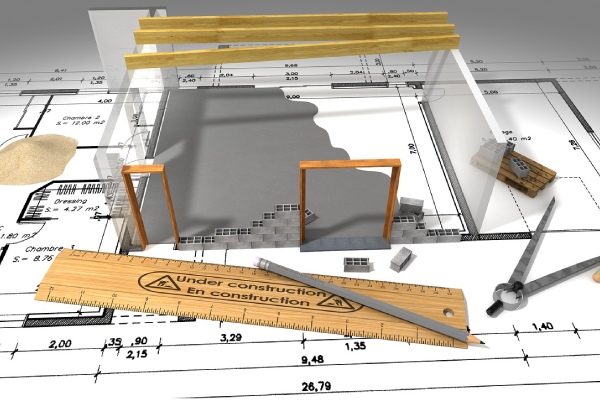

So We Have Work On Progress On Work With Design.3. Functional LayoutS & Floor Plan

Process layouts are facility configurations in which operations of a similar nature or function are grouped together. As such, they occasionally are referred to as functional layouts. Their purpose is to process goods or provide services that involve a variety of processing requirements. we are work on the same process.

4. 3D Designs & 2D Drawings

Advantages of 3D Modeling & 2D Drawings

- Streamlined Product Design Cycles. Scan Data and CAD. ...

- An Accessible Design Process. ...

- Improved Communication Across Internal and External Teams. ...

- Catch Design and Quality Issues Before They Cost You.

.

5. Products & Materials

The three main raw materials used to make pig iron (which is the raw material needed to make steel) for primary steel production in a blast furnace are the processed iron ore, coke (residue left after heating coal in the absence of air, generally containing up to 90% carbon) and limestone (CaCO3) or burnt lime (CaO), which are added to the blast furnace at regular intervals.

6. Implementation

Our product development team draws on a solid foundation in metallurgy, the latest developments in coatings and can-making technology & Implement On time to time. we are best in work.

We support the development of tomorrow's high performance steel packaging solutions. Projects may range from the development of new steel grades, to the design of a new manufacturing process, to assessments to explore how to improve your packaging's performance.